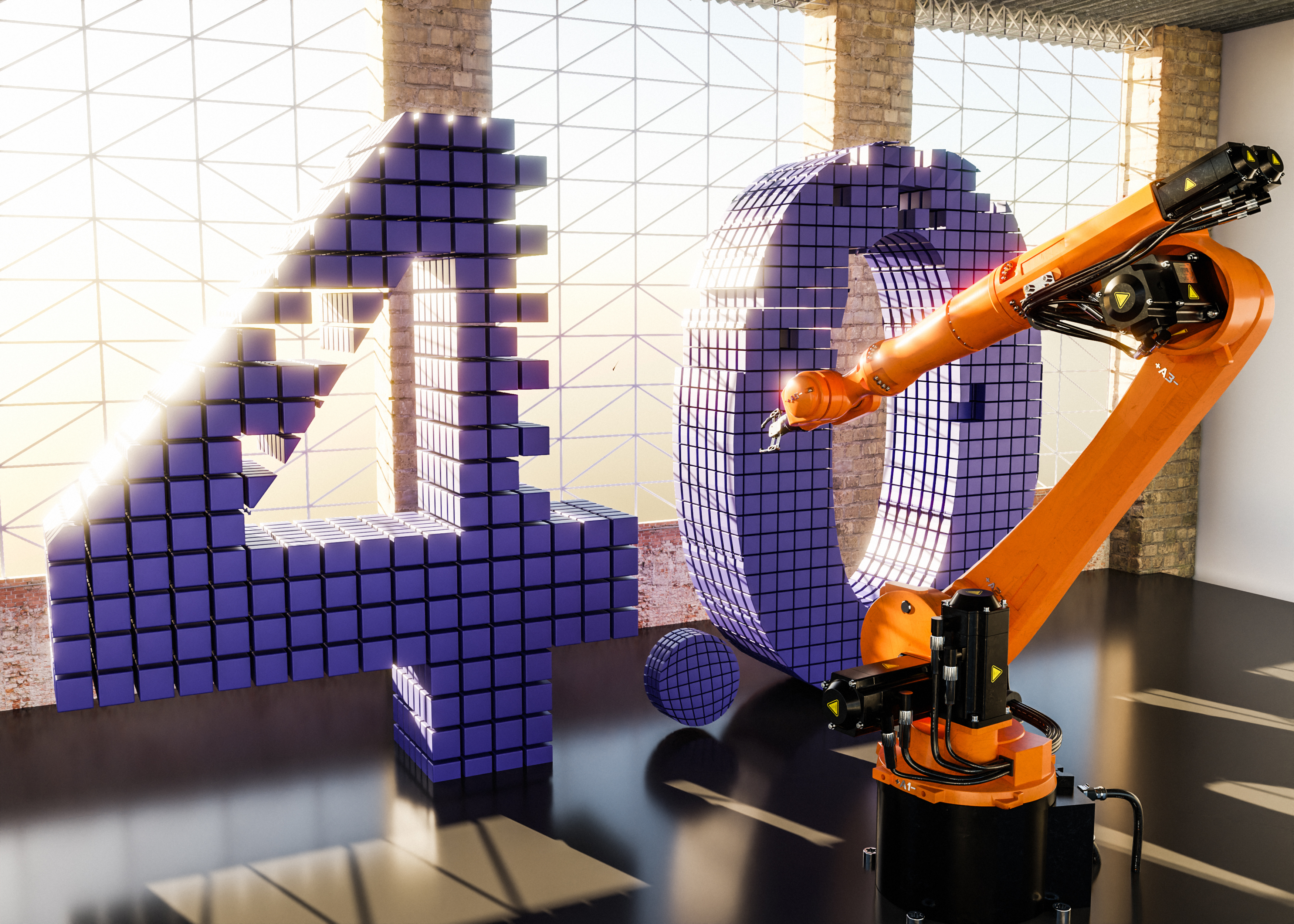

Transforming Manufacturing with Smart, Connected Technologies

Welcome to SJ Automations, where innovation meets precision in the era of Industry 4.0. As pioneers in the manufacturing sector, we harness cutting-edge technologies to redefine production standards and propel businesses towards unprecedented levels of efficiency and sustainability.

We are committed to integrating Industry 4.0 principles into every facet of our operations. From smart factories and connected machines to predictive maintenance and real-time data analytics, we leverage state-of-the-art technologies to optimize production workflows and deliver superior quality products.

The fourth industrial revolution, known as Industry 4.0, is transforming the landscape of manufacturing and industrial operations. At SJ Automations, we are at the forefront of this transformation, providing cutting-edge PLC and SCADA solutions that enable businesses to harness the full potential of Industry 4.0 technologies.

Driving measurable results for forward-thinking manufacturers

Comprehensive technologies to transform your manufacturing operations

Intelligent systems that communicate and make decisions autonomously

Connect your physical assets to the digital world

Transform data into actionable insights

Scalable infrastructure for industrial data

Virtual replicas for optimization and simulation

Minimize downtime and maximize efficiency

Transform your manufacturing operations with our solutions

Automation and real-time data enable more efficient production processes

Adapt quickly to market changes and customer demands

Monitor and control processes with precision for consistent quality

Optimize operations and maintenance to reduce expenses

Real-time data and analytics provide valuable insights

Reduce waste and energy consumption for greener operations

Real-world transformations powered by our solutions

Revolutionizing Manufacturing with Smart Factory Solutions

A large manufacturing plant sought to modernize its operations and improve efficiency across multiple production lines.

We implemented a complete Industry 4.0 solution, including IoT sensors, advanced PLC systems, and cloud-based SCADA with AI analytics.

Production efficiency increased by 35%, and predictive maintenance reduced downtime by 20% within the first year.

Leveraging IoT and AI in Energy Management

An energy provider needed to optimize energy production and distribution across their network with aging infrastructure.

Our IoT-integrated SCADA system provided real-time monitoring and AI-driven analytics for energy optimization.

Energy output optimized by 15%, operational costs reduced by 10%, and carbon footprint decreased by 8%.

Enhancing Quality Control with Digital Twins

A plastics manufacturer aimed to improve product quality and reduce defect rates in their injection molding process.

We created digital twins of critical assets to simulate and optimize production processes in real-time.

Defect rates reduced by 25%, production processes became 30% more efficient, and energy consumption decreased by 12%.

Discover how our Industry 4.0 solutions can transform your manufacturing operations